Frac Stacks & Missiles

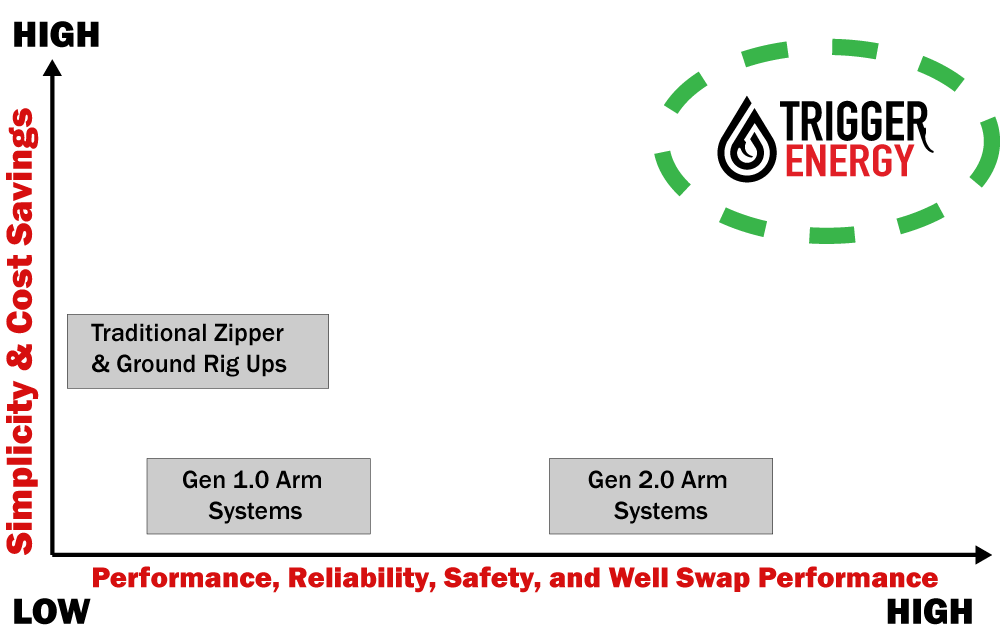

The Frac Rail™ system eliminates at least 50% of the ground iron connections for multiple well completions. Fewer connections means SAFER and FASTER frac rig-ups, fewer opportunities for line leaks and shorter well swap times.

The Frac Rail™ system eliminates at least 50% of the ground iron connections for multiple well completions. Fewer connections means SAFER and FASTER frac rig-ups, fewer opportunities for line leaks and shorter well swap times.

The Frac Rail™ system eliminates at least 50% of the ground iron connections for multiple well completions. Fewer connections means SAFER and FASTER frac rig-ups, fewer opportunities for line leaks and shorter well swap times.

Today’s well completion methods require high-rate, low viscosity fluid and fine mesh proppants. This technique is quite devastating for conventional “Zipper” Manifolds. They are prone to leaks, frequent valve rebuilds and are limited in the number of wells that can be completed simultaneously. The Frac Rail™ system uses large 5″ and 7″ diameter 10k – 15k iron and flanged connections allowing rates up to 120 bpm while virtually eliminating all valve failures.

Today’s well completion methods require high-rate, low viscosity fluid and fine mesh proppants. This technique is quite devastating for conventional “Zipper” Manifolds. They are prone to leaks, frequent valve rebuilds and are limited in the number of wells that can be completed simultaneously. The Frac Rail™ system uses large 5″ and 7″ diameter 10k – 15k iron and flanged connections allowing rates up to 120 bpm while virtually eliminating all valve failures.

75% faster well swaps versus competitors!

120 bpm & 15k psi capability

Less risk of injury, leak, and failure

Reduce ‘Red Zone’ exposure

4.7 minute well swaps

Faster and improved quality of greasing performance

Fewer pressure tests

Frac rig up reduced by 50% or more

Trigger Rig Up

*Trigger Frac Stacks, Frac Rail & Frac Cannon rigged up awaiting horsepower

Conventional Frac Rig Up

Where Integrity Meets Innovation